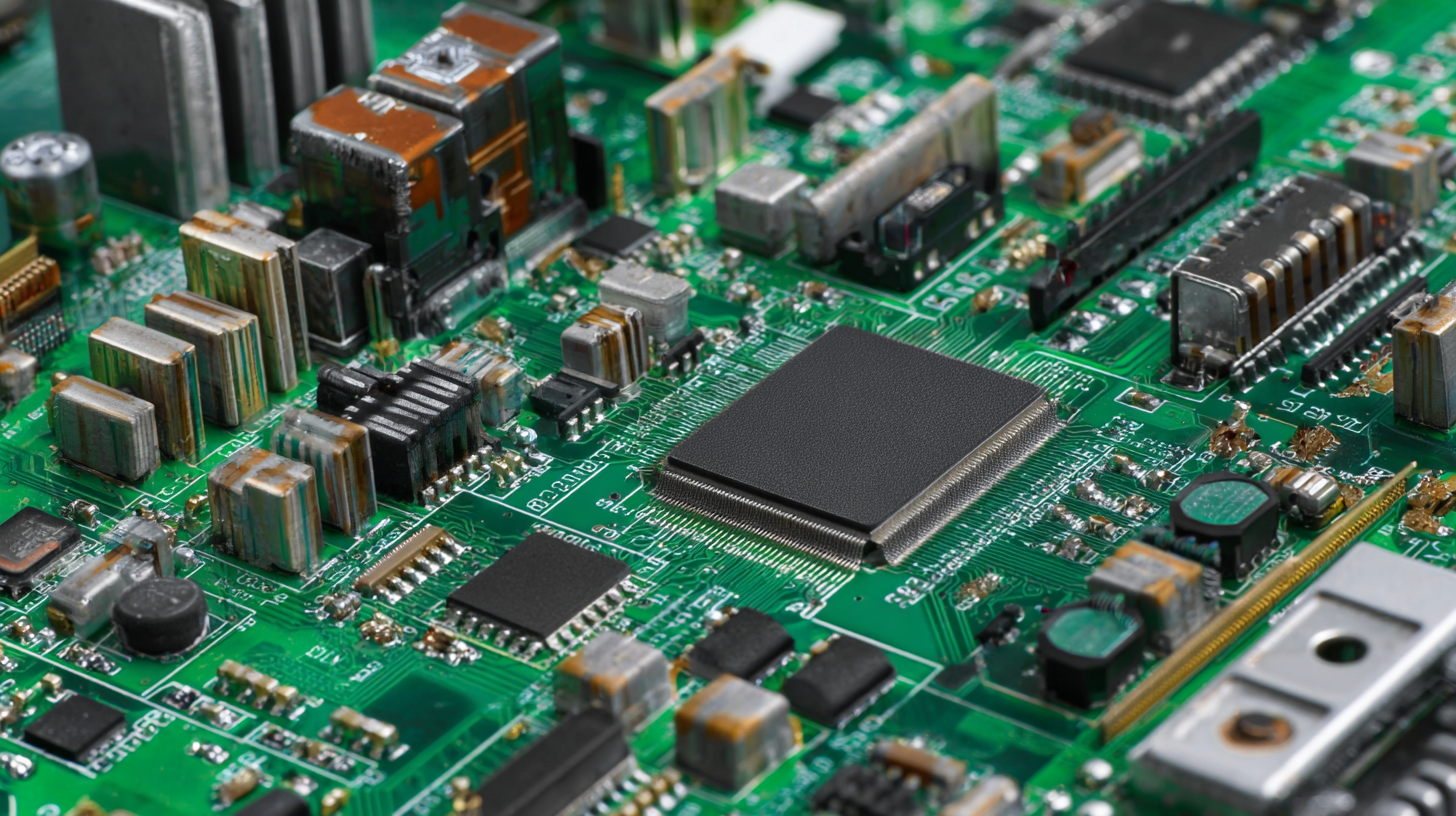

Understanding the Impact of Quality Control in PCB Board Assembly for Enhanced Performance

In the rapidly evolving electronics industry, the significance of quality control in PCB Board Assembly cannot be overstated. As the demand for more sophisticated electronic devices surges, ensuring the reliability and performance of Printed Circuit Boards (PCBs) has become crucial.

According to a report by IPC, the global PCB market is projected to reach $100 billion by 2025, with a substantial portion attributed to advancements in assembly technologies. Effective quality control processes, including rigorous testing and inspection methodologies, are essential in detecting defects early and reducing manufacturing costs.

Research indicates that companies that implement strict quality standards in PCB Board Assembly can reduce their defect rates by up to 30%, thereby enhancing overall product reliability and customer satisfaction. As such, understanding and improving quality control practices in PCB Board Assembly is vital for manufacturers aiming to compete in a technology-driven marketplace.

Identifying Key Quality Control Processes in PCB Assembly

In the realm of PCB (Printed Circuit Board) assembly, the significance of implementing stringent quality control processes cannot be overstated. Key quality control measures include automated optical inspection (AOI), functional testing, and in-circuit testing (ICT). According to a report by IPC, the global market size for PCB assembly is projected to reach $80 billion by 2025, emphasizing the critical role that quality control plays in maintaining competitiveness and ensuring the reliability of electronic products. By incorporating AOI, manufacturers can enhance their defect detection rates by up to 95%, significantly reducing the risk of failures in the field.

Moreover, integrating functional testing within the assembly process allows for real-time identification of performance issues, enabling rapid corrective actions. Research from the National Institute of Standards and Technology (NIST) shows that companies using comprehensive quality control processes can improve their product yield by 30%. Furthermore, in-circuit testing effectively checks individual components on the PCB for performance compliance, ensuring that the final product meets the necessary specifications. Together, these key quality control processes not only enhance the reliability of the PCB assemblies but also contribute to a reduction in overall production costs and time-to-market, highlighting their essential role in the electronics manufacturing industry.

Implementing Effective Testing Methods for PCB Boards

Implementing effective testing methods for PCB boards is crucial in ensuring the reliability and functionality of electronic devices. According to the IPC (Association Connecting Electronics Industries), approximately 30% of PCB manufacturing defects can be traced back to inadequate testing and quality control measures. By adopting comprehensive testing processes, manufacturers can significantly reduce failure rates, improve yield, and enhance overall product performance.

One widely utilized method is Automated Optical Inspection (AOI), which enables manufacturers to detect surface defects such as misalignments and soldering issues, achieving over 90% defect detection rates. Additionally, functional testing involves assessing the complete assembly under real operating conditions, allowing for the identification of intermittent failures that might not be caught during initial inspections.

Reports indicate that companies implementing such rigorous testing methodologies can experience up to a 50% reduction in warranty claims and an increase in customer satisfaction, emphasizing the importance of quality control in PCB board assembly.

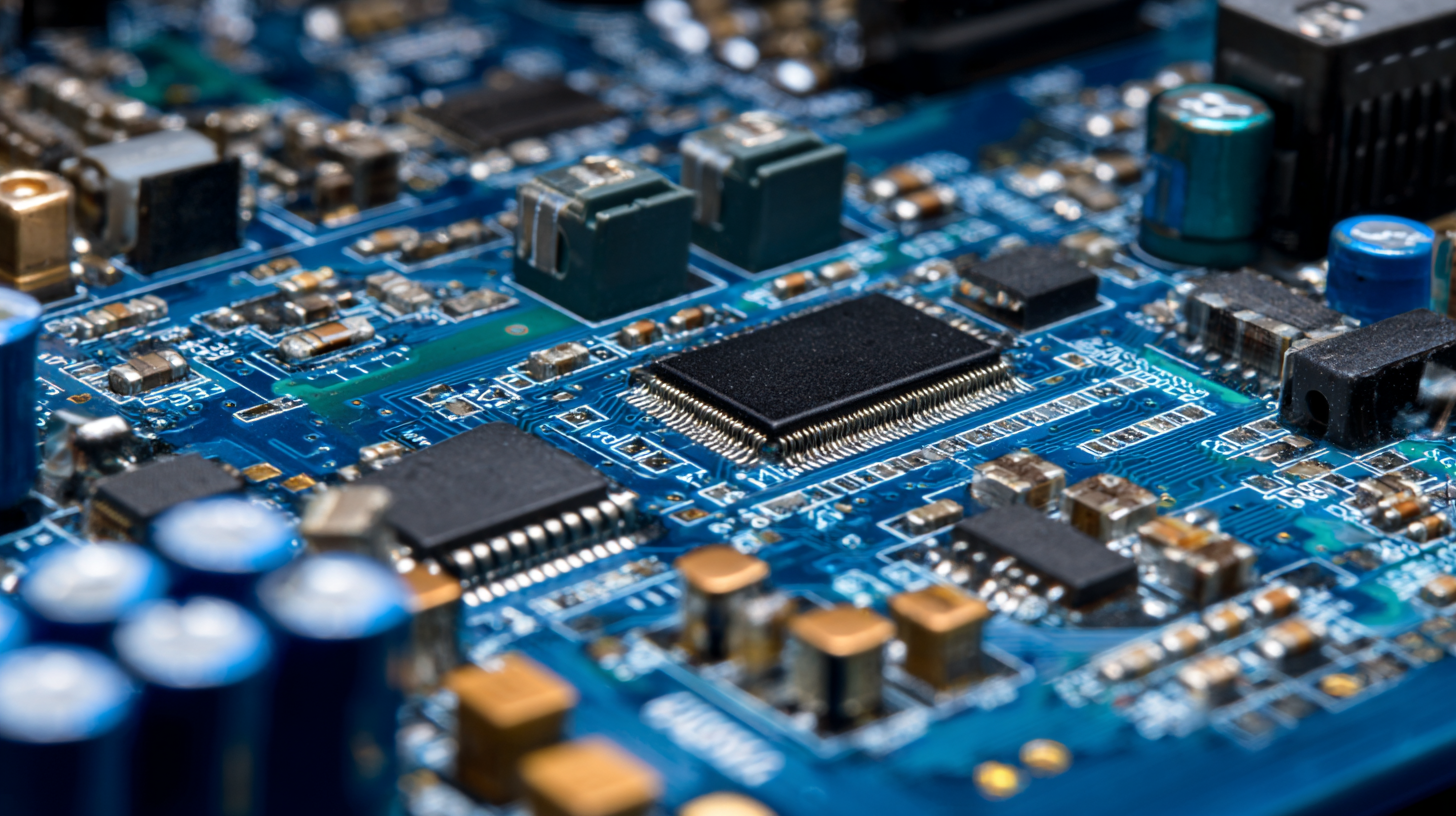

Analyzing the Role of Materials in Quality Assurance

The materials utilized in PCB board assembly play a pivotal role in ensuring quality assurance and enhancing overall performance. Recent studies from the IPC show that nearly 60% of PCB defects arise from poor material selection and handling, underlining the critical importance of quality assurance in materials. High-performance materials, such as FR-4 laminates and advanced solder masks, not only improve the reliability of the connections but also help reduce thermal and electrical stresses that can lead to failure in electronic devices.

Furthermore, employing advanced materials can lead to substantial cost savings in the long run. According to a report by the IPC-Association Connecting Electronics Industries, companies that invest in quality materials experience a 15% reduction in overall defect rates. This is particularly relevant in sectors such as automotive and aerospace, where performance and reliability are non-negotiable. By integrating rigorous quality control measures from raw material procurement to final assembly, manufacturers can ensure that their products meet stringent performance standards while minimizing waste and enhancing sustainability.

Understanding the Impact of Quality Control in PCB Board Assembly for Enhanced Performance - Analyzing the Role of Materials in Quality Assurance

| Material Type |

Quality Control Method |

Defect Rate (%) |

Performance Rating (1-10) |

Notes |

| FR-4 Epoxy |

Visual Inspection |

1.5 |

8 |

Widely used for standard PCBs |

| CEM-1 |

X-Ray Inspection |

2.0 |

7 |

Good for low-frequency applications |

| Polyimide |

Automated Optical Inspection |

0.5 |

9 |

Excellent thermal and chemical resistance |

| Alumina Ceramic |

Functional Testing |

0.8 |

9 |

Used in high-frequency circuits |

| Taconic TLY |

In-Circuit Testing |

1.0 |

8 |

Low dielectric loss for RF applications |

Optimizing Workflow for Enhanced Quality Control in Assembly

Quality control plays a vital role in PCB board assembly, directly influencing the performance and reliability of electronic devices. To optimize workflow for enhanced quality control in assembly, it's essential to implement systematic processes and best practices. Streamlining operations not only reduces the chances of errors but also enhances the overall productivity of assembly teams.

Quality control plays a vital role in PCB board assembly, directly influencing the performance and reliability of electronic devices. To optimize workflow for enhanced quality control in assembly, it's essential to implement systematic processes and best practices. Streamlining operations not only reduces the chances of errors but also enhances the overall productivity of assembly teams.

Tip: Always conduct thorough training sessions for assembly staff to ensure they are well-versed in quality control standards. A knowledgeable workforce can quickly spot potential issues and address them before they escalate.

Additionally, incorporating technology, such as automated inspection systems, can significantly improve quality control during the assembly process. These systems can identify defects at various stages, allowing for immediate corrective actions. Implementing feedback loops where workers can report issues encountered during assembly also encourages proactive quality management.

Tip: Regularly review and update quality control protocols based on assembly line performance. This practice ensures that your quality measures keep pace with evolving technologies and industry standards, thereby safeguarding product integrity.

Best Practices for Continuous Improvement in PCB Manufacturing

In the ever-evolving world of PCB manufacturing, maintaining high-quality standards is crucial for ensuring optimal performance. Best practices in quality control not only help reduce defects but also enhance the overall efficiency of the production process. Implementing systematic approaches to monitor and evaluate the assembly stages can lead to significant improvements and a solid reputation in the industry.

**Tips:** Conduct regular training sessions for your team to ensure that everyone is familiar with the latest quality control protocols and industry standards. This knowledge can empower employees to identify potential issues before they escalate, fostering a proactive quality-oriented culture.

Additionally, incorporating automated inspection technologies can vastly improve detection rates of faults during assembly. These systems provide real-time feedback and data analysis, allowing for immediate corrective actions.

**Tips:** Utilize statistical process control (SPC) charts to monitor key metrics such as defect rates and operational efficiency. By analyzing this data, manufacturers can make informed decisions and continuously refine their processes, leading to sustained improvements in product quality.