Harnessing the Power of Chinese Manufacturing for the Finest Printed Boards

In the rapidly evolving landscape of technology and manufacturing, the significance of high-quality printed boards cannot be overstated. China, with its unparalleled industrial capabilities and advanced manufacturing techniques, stands at the forefront of printed board production. This blog explores the potential of harnessing Chinese manufacturing prowess to create the finest printed boards that meet the demands of modern electronics. By integrating digital technologies and implementing best practices, manufacturers can enhance efficiency, reduce costs, and ensure superior quality in their printed board offerings. As we delve deeper into the strategies and tips for optimizing manufacturing processes, it becomes evident that collaboration and innovation are key drivers in elevating printed board manufacturing to new heights. Join us as we uncover how to leverage China's manufacturing strengths to achieve excellence in printed board production.

Identifying the Key Qualities of Top Chinese Printed Board Suppliers

The landscape of printed circuit board (PCB) manufacturing is intricately tied to the advancements in technology and supply chains, particularly in China. As the world's leading manufacturer of PCBs, Chinese suppliers offer distinct advantages that stem from a combination of cost efficiency, innovative capabilities, and a robust network of electronic components. According to industry reports, China's PCB production accounts for nearly 50% of the global market share, underlining its pivotal role in electronics manufacturing.

Key qualities to look for in top Chinese printed board suppliers include advanced manufacturing processes, stringent quality control measures, and the ability to handle complex designs. Many leading suppliers have adopted state-of-the-art technology to enhance production efficiency, with some reporting a 20% reduction in lead times through automation and lean manufacturing practices. Furthermore, as China evolves into a major innovator in advanced industries, it’s essential for companies to collaborate with suppliers that not only meet current demands but also anticipate future trends in technology and design.

With ongoing shifts in the global supply chain landscape, identifying suppliers with a commitment to innovation and quality becomes critical for businesses looking to thrive in competitive markets.

Evaluating Supplier Credentials: Certifications and Industry Experience

When selecting a supplier for printed circuit boards (PCBs), evaluating their credentials is paramount. Certifications play a crucial role in ensuring that a supplier adheres to industry standards and best practices. Quality certifications such as ISO 9001 and IPC standards not only reflect a company’s commitment to quality assurance but also their capacity for innovation and continuous improvement. These certifications serve as benchmarks, providing insight into a supplier's operational procedures, reliability, and overall performance.

In addition to certifications, industry experience must also be considered. The length of time a supplier has been in business often correlates with their knowledge of market dynamics and production capabilities. Seasoned suppliers are likely to have faced various challenges and have evolved their processes to enhance efficiency and product quality. Collaborating with a manufacturer that has extensive industry experience can result in smoother communication and a deeper understanding of your specific requirements, ultimately leading to better outcomes in your PCB projects.

Understanding Manufacturing Capabilities: Technology and Equipment Insights

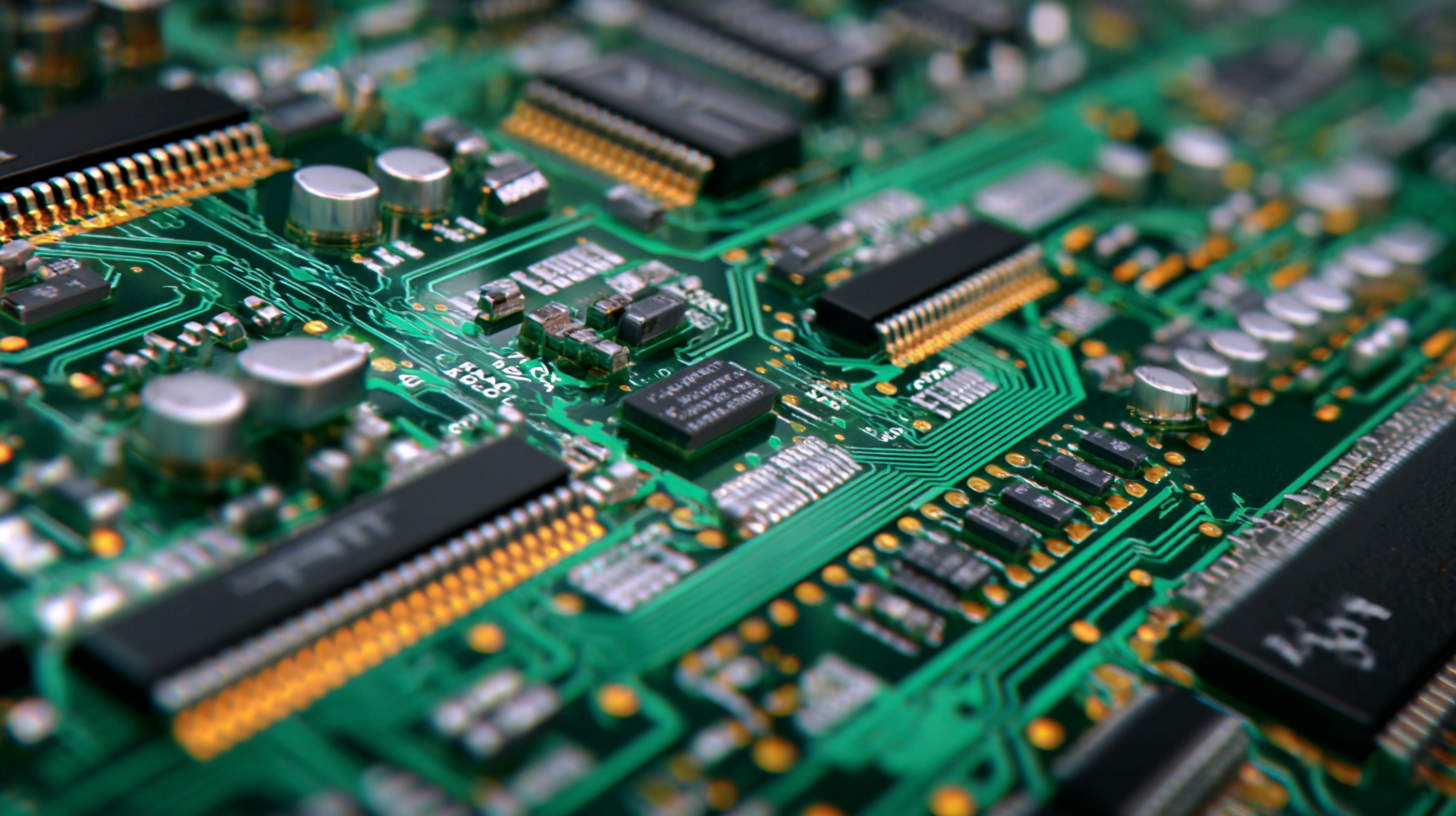

Chinese manufacturing continues to evolve at an impressive pace, especially in the realm of printed circuit boards (PCBs). The integration of advanced technology and state-of-the-art equipment has positioned China as a leader in PCB production. Manufacturers are employing automated processes and sophisticated machinery, such as high-speed pick-and-place machines, to enhance precision and efficiency. This technological prowess not only streamlines production but also ensures the highest quality standards, which are crucial for industries ranging from consumer electronics to automotive applications.

Moreover, the investment in research and development has led to innovative manufacturing capabilities that cater to various client needs. For instance, specialized equipment like laser machining and advanced soldering technologies allow for the creation of intricate designs and multi-layered boards. This versatility enables manufacturers to produce complex PCBs that meet the demands of modern electronics. As global markets continue to expand, China's capacity to adapt and integrate cutting-edge technology into its manufacturing processes remains a significant asset, promising exceptional quality and performance in printed board solutions.

Harnessing the Power of Chinese Manufacturing for the Finest Printed Boards - Understanding Manufacturing Capabilities: Technology and Equipment Insights

| Manufacturing Capability |

Description |

Technology Used |

Production Volume (units/month) |

Lead Time (days) |

| High-Density Interconnect (HDI) |

Advanced technology for complex circuit designs |

Laser drilling, Electroplating |

50,000 |

15 |

| Flexible Printed Circuits (FPC) |

Thin, lightweight circuits that can bend |

Photo-etching, Roll-to-roll processing |

30,000 |

20 |

| Multilayer Boards |

For complex electronic devices with multiple layers |

Through-hole plating, Blind/buried vias |

25,000 |

25 |

| Metal Core PCBs |

Enhanced thermal management for high-power applications |

Stamping technology, Thermal transfer |

15,000 |

30 |

| High Frequency PCBs |

Ideal for RF applications and high-speed designs |

Dielectric substrate technology, EPS |

10,000 |

40 |

Assessing Communication and Customer Support from Suppliers

When it comes to sourcing printed circuit boards (PCBs), the role of effective communication and customer support from suppliers cannot be overstated. A report from IPC—Association Connecting Electronics Industries indicates that nearly 65% of manufacturers consider supplier communication as the key factor influencing their satisfaction levels. In China, this is particularly crucial given the fast-paced nature of technological advancements and the varying specifications required by clients around the world.

One of the standout features of Chinese manufacturers is their ability to offer multilingual support and round-the-clock service, catering to a global client base. According to a survey by Statista, over 70% of PCB buyers acknowledged that good customer service significantly impacts their decision to continue business with a supplier. Enhanced support systems, including live chat and dedicated account managers, have become a standard expectation, reflecting a shift towards a more customer-centric approach in the Chinese manufacturing sector. This emphasis on open communication not only fosters trust but also leads to quicker resolution of issues, ultimately streamlining project timelines and enhancing product quality.

Negotiating Contracts and Pricing Strategies for Optimal Collaboration

In the evolving landscape of international trade, effective negotiation strategies are crucial for leveraging the strengths of Chinese manufacturing in printed circuit boards. As companies strive to navigate complex supply chains, establishing transparent and collaborative contract negotiations becomes essential. Businesses should focus on building long-term relationships with suppliers, which can foster trust and lead to more favorable terms.

**Tip 1:** Emphasize Open Communication: Maintain regular dialogue with suppliers to ensure that both parties have a clear understanding of expectations and requirements. This reduces misunderstandings and promotes a smoother negotiation process.

With the peak season approaching, it’s essential to have robust strategies in place. Companies must be proactive in negotiating terms that accommodate seasonal demands while also securing competitive pricing. Being flexible and willing to explore various pricing models can yield positive outcomes for both businesses and suppliers.

**Tip 2:** Leverage Data-Driven Insights: Analyze historical sales data and market trends to inform your pricing strategies. This can help articulate the value proposition to suppliers during negotiations and lead to better pricing outcomes.

In addition, integrating strategic sourcing practices can enhance a company's ability to respond to market fluctuations. By understanding the intricacies of the supply chain and aligning negotiation tactics accordingly, businesses can optimize their collaboration with Chinese manufacturers and ensure a consistent supply of high-quality printed boards.

Harnessing the Power of Chinese Manufacturing for the Finest Printed Boards

This bar chart represents key data metrics for Chinese manufacturing of printed boards in 2023. The production volume, lead time, quality score, and cost per unit are critical factors for organizations looking to optimize collaboration in contract negotiations.